Are quality raw materials important to you?

Cleveland Wire Cloth uses only the finest quality weaving wire, made by select, proven suppliers. Chemical and Physical Certifications alone may not always guarantee overall product quality.

Our product certifications are only signed and notarized by Cleveland Wire Cloth corporate officers. Chemical certifications from vendor wire suppliers are thoroughly analyzed and checked for accuracy with PMI. All wire lot numbers are tracked within unique weaving runs.

Further, even when Chemical Certifications meet a particular specification, screen life and product quality may still be affected by the surface and grain characteristics of the wire itself. Poor quality wire drawing techniques or tools; improper solution annealing; inferior weaving looms; and other factors can all contribute to poor quality wire cloth.

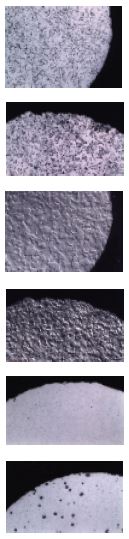

These photographs show samples of Stainless Steel wire, drawn in China, which had been improperly solution annealed resulting in chromium carbide precipitation. The precipitation of chromium carbide effectively reduces the localized chromium content, the element that most contributes to stainless steel’s corrosion behavior.

Annealing at too high a temperature creates grain boundary coarsening, exhibited by a well-defined, large equiaxed grain structure, which will increase the susceptibility to intergranular corrosion — yielding inferior wire cloth.

Since 1914, Cleveland Wire Cloth has worked with only select wire suppliers to assure you of a consistent, high quality, finished product.